Backflow Testing Services

Backflow testing is a critical process to ensure the safety and integrity of a water supply system. It involves inspecting backflow prevention devices to confirm they function correctly, preventing contaminated water from flowing back into the potable water system. Regular testing helps identify potential issues early, reducing the risk of water contamination and property damage.

The optimal time for backflow testings depends on local regulations, seasonal conditions, and system usage. Typically, annual testing is recommended to maintain compliance and system reliability. Testing schedules may vary based on the type of backflow prevention device and the water system’s complexity.

Testing is often performed before peak usage seasons, such as spring and summer, to ensure systems are functioning properly during high demand.

Many jurisdictions require annual backflow testing to adhere to local water safety standards and prevent violations.

Scheduling testing during routine maintenance periods minimizes disruption and ensures continuous system protection.

Testing during moderate weather conditions reduces the likelihood of delays caused by extreme cold or heat.

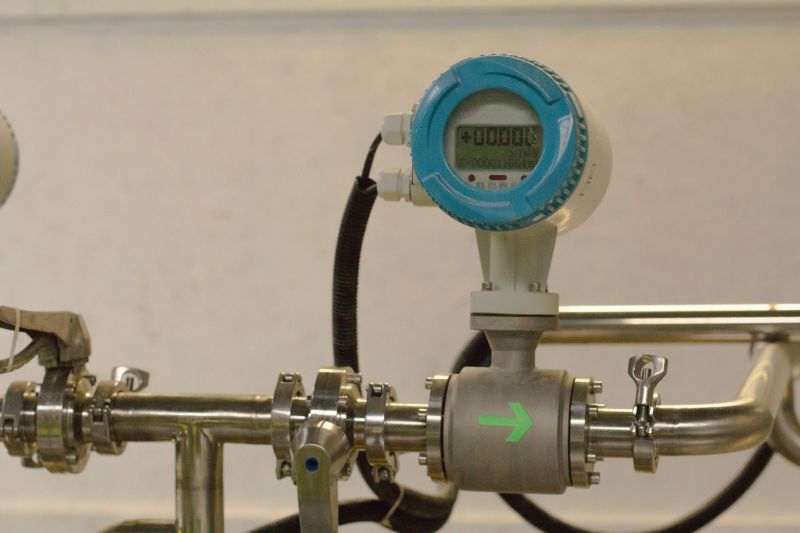

Technicians inspecting backflow preventers ensure proper operation.

Specialized tools used to verify device functionality.

Calendar reminders for annual backflow testing schedules.

Ways to make Backflow Testings work in tight or awkward layouts.

Popular materials for Backflow Testings and why they hold up over time.

Simple add-ons that improve Backflow Testings without blowing the budget.

| Aspect | Details |

|---|---|

| Frequency | Typically once a year, depending on jurisdiction. |

| Optimal Seasons | Spring and early summer are common times. |

| Weather Impact | Avoid extreme cold or heat for testing. |

| Regulatory Deadlines | Meet local compliance testing deadlines. |

| System Usage | High demand periods may require more frequent testing. |

| Maintenance Schedule | Coordinate with routine system maintenance. |

| Device Type | Different devices may have varying testing intervals. |

Regular backflow testing is essential for maintaining water safety and compliance. Scheduling tests during appropriate seasons and conditions ensures accuracy and minimizes disruptions. Proper timing helps prevent costly repairs and potential health hazards caused by backflow contamination.

A technician checks the backflow prevention device.

Proper tools are used for accurate testing.

Comprehensive inspection of water lines.

Final verification of device operation.

High-end options that actually feel worth it for Backflow Testings.

Finishes and colors that play nicely with Backflow Testings.

Little measurements that prevent headaches on Backflow Testings day.

A 60-second routine that keeps Backflow Testings looking new.

Interested in scheduling backflow testing? Filling out the contact form can help coordinate the appropriate timing and ensure your water system remains compliant and safe.